CEBA Built by the Best Finalist

Agile Cold Storage engaged Fisher Construction Group to design and build a state-of-theart Automated Storage and Retrieval System (ASRS) facility in Gainesville, Georgia. “Agile reached out to us because of the complexity of the ASRS and our reputation in the industry; there are not many contractors that specialize in that cold storage ASRS world. Because of our expertise, they trusted that we knew what we were doing,” says Reece Esary, Project Manager for Fisher. “If you’ve never built one of these, you can mess it up quickly by not asking the right questions or involving the right partners.”

As the population continues to grow and available buildable land becomes scarcer, the ASRS building model optimizes storage capacity by utilizing vertical space. Additionally, given the difficulty in finding workers willing to operate in cold storage environments, the ASRS design reduces the labor required per pallet position, enhancing efficiency and operational sustainability.

Having been involved since the first week, Esary budgeted and managed expenses throughout the project. He was on the ground from the first movement of dirt to the project’s completion. The same was true for the project engineer and superintendent.

“At Fisher, we structure our project teams to have the same team members involved from the start through completion,” Esary says. “This ensures that items don’t get dropped or missed. This helps as there is a main point of contact that has been involved from the beginning. Safety-wise, having more eyes on site and paying attention, we can catch things before they become major issues.”

Construction began in early 2023, with the foundation pouring completed by April, followed by the installation of steel. The facility, designed as a large blast freezer, features 48,360 pallet positions within a 92,000-square-foot building that supports six cranes. It maintains a final operating temperature of -10°F, enabling rapid cooling of products arriving warm from processing.

“One of the most notable aspects of the project is we were able to stay under budget and return those savings to the client,” Esary says. “We also met the contractual schedule and beat that by a couple of weeks.”

Getting to Work

Fisher partnered early with Agile to tailor a solution that addressed the site’s unique challenges, such as the fact the facility was nestled on a large hill at the entrance to the active cold storage operation. Consequently, the project posed significant design, construction, and logistical hurdles.

“We knew there were a lot of complexities with the project site,” Esary says. “There was a huge slope, and there are stringent tolerances for the slab and automation equipment that you have to meet. The differential settlement of the ASRS slab should be almost negligible, and we had to coordinate with our ground approvement contractor at the front end to see if it was even feasible.”

Strategically located five hours from the Port of Savannah, the site benefits from lower wages and its proximity to processing plants, which reduces operational costs and allows for savings to be passed on to customers.

From the beginning, Fisher’s team addressed the challenging sitework amid record rainfall in northeast Georgia. To stabilize the hillside, Fisher built concrete shoring walls with soil nails extending 20 to 25 feet deep into the surrounding soil, while part of the ASRS slab was supported by H-piles driven down to bedrock.

The site was located on a large hill, posing significant design, construction, and logistical hurdles. (Photo courtesy of Fisher construction Group).

“We had to build retaining walls with some tiebacks back to the existing facility,” Esary says. “That added to the complexity.”

Another challenge arose because Fisher was building next to an existing facility, leaving only about 25 feet of space. Additionally, the retaining walls limited the amount of equipment that could be placed above them between the existing and new buildings.

“You have to distribute the load with road plates and only specific equipment could be used in this space, so there was just more complexity there,” Esary says.

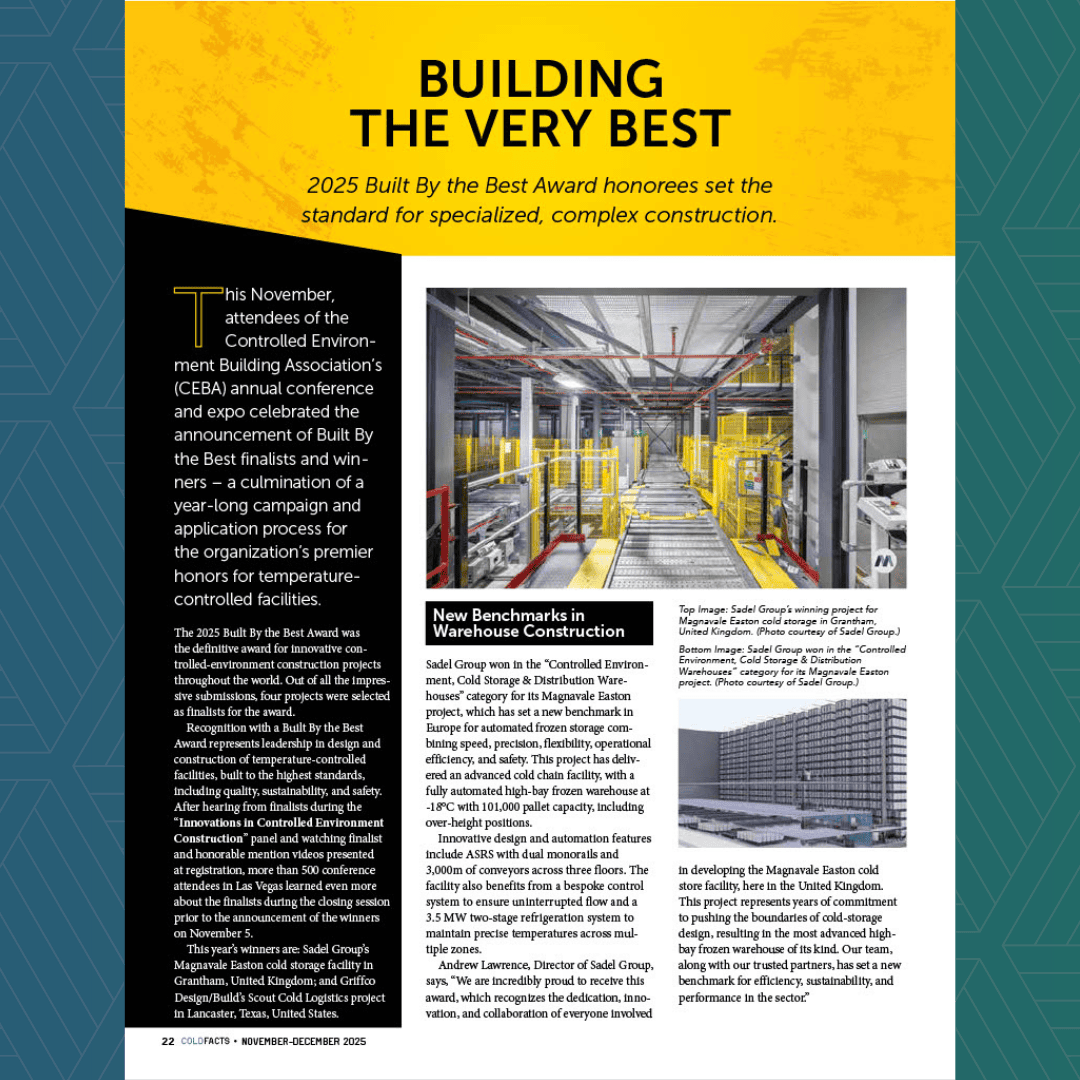

Over 11,000 cubic yards of concrete were poured safely and efficiently, all while keeping the existing cold storage operation running smoothly. The massive steel rack structure, supplied by Frazier Industrial, comprises 9.6 million pounds of steel and stands 125 feet tall. It was delivered on time and within budget, meeting the strict tolerance requirements of Swisslog’s automation systems.

The facility has six automated cranes supplied by Swisslog. Each crane is equipped with a pallet mole that extends as the crane moves down an aisle to retrieve a pallet. The mole collects the pallet and brings it back to the crane, then the pallet is transported via an automated conveyor system to the dock.

“In terms of construction, we built the facility in four ‘blocks,’ which is a phased approach,” Esary says. “Working from the dock over to the backside of the ASRS, you have to get 50% of the rack up and tight before you can start putting IMP panels on and start decking.”

Esary explained that by putting on the IMP panels, you’re creating a “giant sail,” making it challenging in high winds, so it’s vital to time things correctly.

“Right around the 50% completion mark is when you get the automator on-site, because they have to put their rail in, where the cranes get installed on, and then you have to get the cranes installed inside the building before they close it up,” Esary says.

Fisher also undertook the design and construction of a 24,150-square-foot loading dock equipped with an automated conveyor system. Most of the refrigeration equipment, including six ALTA units, was situated on the roof of the loading dock, adding 435,000 pounds of weight to the structure.

Fisher undertook the design and construction of a 24,150-square-foot loading dock equipped with an automated conveyor system. (Photo courtesy of Fisher Construction Group).

Innovative Thinking

A significant success of the job, and once again, a reason Fisher was hired for the project, was getting all the tolerances correct between the automater and the racking supplier manufacturer, which required extensive coordination between the two.

Innovation played a crucial role throughout the project. Fisher’s team designed the ASRS buildings at a lower elevation than the loading dock – an uncommon feature – enabling the cranes to retrieve products from any height within the system. This design not only reduced the overall building height, helping to comply with local height restrictions, but also maximized site utilization on limited land.

An inspection corridor beneath the cantilevered loading dock was engineered with glycol tubes and temperature sensors to prevent freezing, making routine maintenance easier in a challenging environment.

Another key innovation was the integration of six rooftop ALTA refrigeration units with the roof-mounted refrigeration equipment, which added approximately 435,000 pounds of weight but provided energy-efficient cooling.

The Fisher team also utilized a complete lightning protection system. Given that Georgia is prone to many lightning storms throughout the year, sometimes weekly during the summer months, this was an important aspect since the ASRS-type structures typically are the tallest structures for miles. A single lightning strike can damage the entire system, so the Fisher team decided to install a lightning protection system. The ASRS is fully automated with many sensitive components, and they wanted to keep the building protected.

A Top Team

One of the goals Fisher pursued on this project, and is recognized for, is meeting expectations regarding schedules.

“You have to time things right to make sure everyone is on the same page as to when these things need to be completed,” Esary says. “A lot of the automators are from overseas and so a lot of the equipment is being shipped across the Atlantic, and if you don’t have equipment/ materials getting there in time, you’re delayed. You may have 40 to 50 rack employees on-site and if they’re sitting around all day, it costs you tens of thousands of dollars. It is so important that things are coordinated and everything is aligned.”

Fisher’s collaborative approach ensured all stakeholders, from Agile to subcontractors, were aligned. Esary notes that this approach simplifies the management of complex projects and helps to overcome significant obstacles.

For example, during the project, when unexpected bedrock was discovered on site, impacting the additional truck parking requested by the client, the company collaborated with all parties involved to redesign the site. This allowed Fisher/Agile to retain the truck parking, reduce costs compared to the original plan, and keep the project on track – all without compromising the schedule.

“Our team strives to work side by side with clients, consultants, and trade partners,” Esary says. “We treat all our partners as if we are all on the same team with the same goal. We make it apparent that we expect everyone to buy in to the same common goal. By bringing in insight from various levels of experience, we create a valued-engineered solution. By listening to different opinions and being open to others’ ideas, this is a key element to meet and exceed the client’s expectations.”

“Our team delivered a complex, high-tech project on time, under budget (by more than $1 million) and with safety and quality at the forefront,” Esary says. “It’s a testament to the power of teamwork and innovative thinking in overcoming challenges and exceeding client expectations.”

John Ripple, Chief Development Officer for Agile Cold Storage, called the finished project exceptional and noted the job was completed with a high level of professionalism and accuracy.

“The end result speaks for itself,” Ripple says. “The ASRS started up flawlessly. The project was completed millions of dollars under budget. And the planning process has already begun for a second system of the same design with the same team, led by Fisher Construction Group.”

Media Contact

For media inquiries, please contact: Lindsay Shelton-Gross, Senior Vice President, Global Communications, Marketing and Strategic Initiatives, Global Cold Chain Alliance.