CEBA Built by the Best Finalist

Emergent Cold LatAm, one of the fastest growing refrigerated storage and logistics providers in Latin America, aimed to expand a cold storage facility in Talcahuano, a Chilean region known for seafood and fruit production.

The company selected Cubic33 Group, based in Barcelona, Spain, for the project. Once completed, the facility would be the largest frozen food warehouse in Chile and one of the largest in Latin America, with 37,000 pallets and 323,000 square feet of space.

“We built cold storage for Emergent in Spain in 2015, and they knew that we had operated in Peru,” says Gonzalo Chivite, Chief Operating Officer and Partner for Cubic33 Group. “So, in 2019, we built Emergent’s first project in Peru.”

Following the COVID-19 pandemic, Emergent wanted to grow, and this was one of the first projects it initiated. The company had recently acquired Friopacífico in the region, and it intended to modify and expand the facility.

Joaquín Del Campo, Managing Director for the Pacific Region at Emergent Cold LatAm, emphasized the strategic significance of this investment, noting the company’s dedication to supporting Chile’s seafood and agriculture sectors is unwavering.

“The rise in mackerel quotas, along with expanding Coho salmon and individually quick frozen fruit production, necessitates upgraded temperature-controlled storage capacity – this new facility perfectly meets that need,” Del Campo says.

Chivite explains that the facility in Talcahuano, Chile, was designed to store and process products at high risk of spoilage, leading to a new processing and distribution approach that became a game-changer in the industry.

“We had exactly 12 months to deliver because the fishing season was starting in January of the following year, and the project would only be worthwhile if it was ready for the fishing season,” Chivite says. “It started in December 2023, and we had no permits yet, but we needed to be done in a year.”

Cubic33 exceeded expectations by completing the facility in just 10 months, two months ahead of the end of the fishing season.

To ensure smooth operations, the Cubic33 Group team frequently met with local authorities to proactively secure necessary regulatory approvals and collaborate on solutions to potential challenges before they occurred.

“We had full collaboration,” Chivite says. “The steel mill in the city was closing, so a lot of families were losing their jobs. Suddenly, this project emerged, offering job opportunities to those who may have recently lost their own. As a result, certifications and permits went smoothly, and the city officials were welcoming and helpful throughout.”

Innovation on the Job

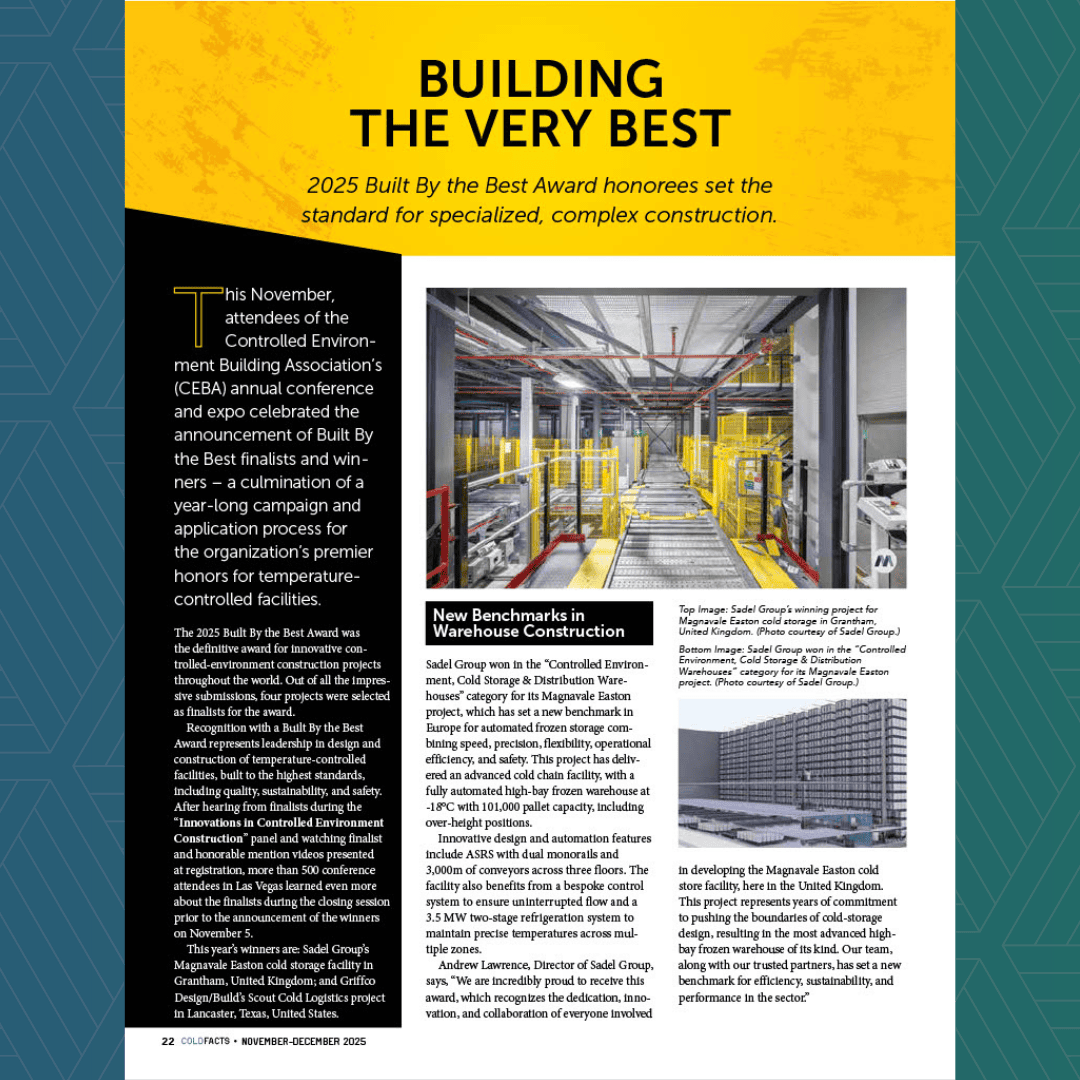

Emergent Cold LatAm’s Talcahuano facility incorporated numerous new technologies, materials, and methodologies to improve the efficiency and effectiveness of the building.

“Many things that were common to us were not done over there,” Chivite says. “Many of the controls were completely new for that market.”

For example, Chivite highlights the use of steel-fiber reinforced concrete for the slabs, which allowed the team to reduce the number of construction joints and create areas up to 10,000 square feet where joints weren’t necessary.

“Other innovations included heated slabs and rapid doors associated with air curtains, which reduced air exchange between environments and minimized ice accumulation inside the chambers,” Chivite says. “While a number of these solutions are common in the United States and Europe, this was the first time they were implemented in Chile.”

Top Challenges

One of the biggest challenges of the project was the tight schedule. Chivite pointed out that the period between investment approval and the first day of operation was very short, requiring the team to work on design, obtaining permits, and starting construction simultaneously.

Component availability also posed difficulties, as the Chilean market lacked many of the required items, forcing the team to import goods from more than 25 different locations. Being in a relatively remote area meant that transporting these materials to the site demanded meticulous planning.

Weather further complicated progress, as construction began during the rainy season. Approximately 70% of the project was completed in heavy winds and rain, making tasks like earthworks and footing installation more challenging.

Additionally, Talcahuano is located in one of the most seismically active regions in the world. As a result, approval, review, and execution times took longer due to heightened safety requirements.

“The local culture had methods for managing the project that were challenging,” Chivite says. “The construction’s overlapping activities were not common practice for the local subcontractors. The only way to meet the deadlines was to bring people in from overseas.”

The project imported the metal structure from Brazil, insulated panels from Spain, doors from Italy, and other materials from Japan and elsewhere.

“The logistics were really tough,” Chivite says. “We had to leverage all our networks worldwide to meet the deadline. If we had missed that date, the project would have been delayed by a year.”

International Team

Chivite credits a multicultural and diverse team with helping to successfully complete the project as the local workers were not accustomed to the methodologies of building so quickly.

“The project involved providers and an engineering team from 13 nations,” Chivite says. “Both the local population and the engineering and management team underwent a mutual adaptation process – locals familiarized themselves with new construction methods and cultural practices, while the external team adjusted to the realities of the local market.”

Sustainable Mindset

The project was specifically designed to achieve the highest EDGE (Excellence in Design for Greater Efficiency) certification and successfully reached this goal through significant sustainability efforts: 46% energy savings, 51% reduction in water use, and 37% lower embodied carbon in materials.

Furthermore, the facility’s structural and electrical design was carefully planned to maximize the use of the entire roof surface for the installation of solar panels.

“This was a general concern for Emergent, so we proposed from day one that we would approach this sustainably,” Chivite says. “All the things like the treatment of water, the insulation, and electrical consumption were considered as part of the design. We wanted to get the maximum level of certification with EDGE.”

A Job Well Done

The completed building features four chambers, and since the first chamber was finished early, the first pallets could be installed sooner than originally planned.

“That was part of the design strategy – all of the refrigeration system was designed to allow segregation, so you could disconnect the chambers,” Chivite says. “When we realized we could deliver earlier, we used that design feature to deliver perhaps not 100% of the building but some of the building’s capacity sooner.”

Emergent considered the project a success and brought back Cubic33 Group to complete an expansion in December 2024, which is now fully operational.

“We were quite happy with the result,” Chivite says. “The biggest thing is to have an American client and be the bridge to what they expect to have in the U.S. market and adapt those specs and standards to build in Chile. Having their support went a long way.”

Media Contact

For media inquiries, please contact: Lindsay Shelton-Gross, Senior Vice President, Global Communications, Marketing and Strategic Initiatives, Global Cold Chain Alliance.