Evans General Contractors brings RL Cold Facility to Life

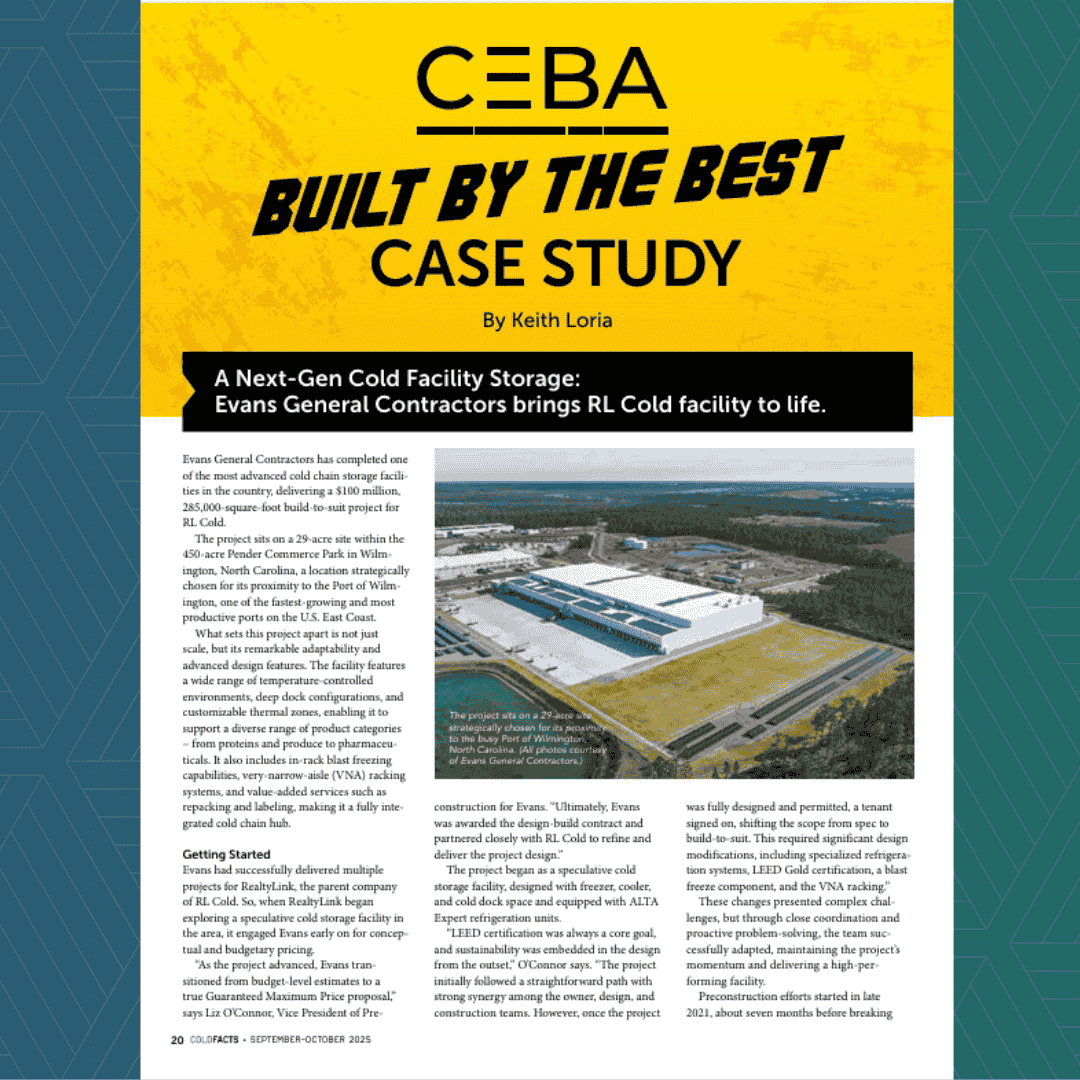

Evans General Contractors has completed one of the most advanced cold chain storage facilities in the country, delivering a $100 million, 285,000-square-foot build-to-suit project for RL Cold.

The project sits on a 29-acre site within the 450-acre Pender Commerce Park in Wilmington, North Carolina, a location strategically chosen for its proximity to the Port of Wilmington, one of the fastest-growing and most productive ports on the U.S. East Coast.

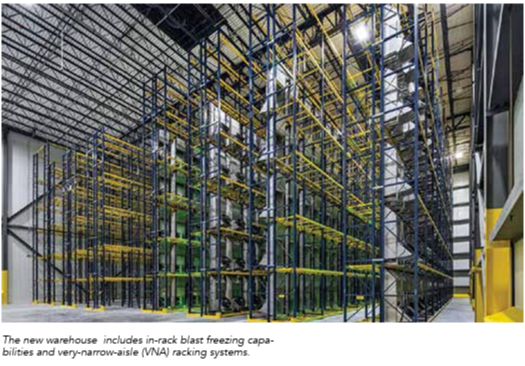

What sets this project apart is not just scale, but its remarkable adaptability and advanced design features. The facility features a wide range of temperature-controlled environments, deep dock configurations, and customizable thermal zones, enabling it to support a diverse range of product categories – from proteins and produce to pharmaceuticals. It also includes in-rack blast freezing capabilities, very-narrow-aisle (VNA) racking systems, and value-added services such as repacking and labeling, making it a fully integrated cold chain hub.

Getting Started

Evans had successfully delivered multiple projects for RealtyLink, the parent company of RL Cold. So, when RealtyLink began exploring a speculative cold storage facility in the area, it engaged Evans early on for conceptual and budgetary pricing.

“As the project advanced, Evans transitioned from budget-level estimates to a true Guaranteed Maximum Price proposal,” says Liz O’Connor, Vice President of Pre-construction for Evans. “Ultimately, Evans was awarded the design-build contract and partnered closely with RL Cold to refine and deliver the project design.”

The project began as a speculative cold storage facility, designed with freezer, cooler, and cold dock space and equipped with ALTA Expert refrigeration units.

“LEED certification was always a core goal, and sustainability was embedded in the design from the outset,” O’Connor says. “The project initially followed a straightforward path with strong synergy among the owner, design, and construction teams. However, once the project was fully designed and permitted, a tenant signed on, shifting the scope from spec to build-to-suit. This required significant design modifications, including specialized refrigeration systems, LEED Gold certification, a blast freeze component, and the VNA racking.”

These changes presented complex challenges, but through close coordination and proactive problem-solving, the team successfully adapted, maintaining the project’s momentum and delivering a high-performing facility.

Preconstruction efforts started in late 2021, about seven months before breaking ground. Construction lasted approximately 13 months, with the project completed on time and within budget, despite the introduction of scope changes midway.

Sustainability and ESG Commitments

From the outset, Evans and RL Cold committed to making the Wilmington facility one of the most modern and sustainable cold storage projects in the country. The building was designed to achieve LEED Gold certification, showcasing a comprehensive suite of sustainability measures.

The project incorporates a 1-megawatt rooftop solar array, which helps offset the significant energy demands of a cold storage warehouse. Water conservation was also a major focus, with a 50,000-gallon rainwater capture system designed to collect rain and condensate for reuse, significantly reducing potable water consumption.

At the heart of the cooling system is an ammonia/CO₂ cascade refrigeration plant with adiabatic cooling, a state-of-the-art solution that improves efficiency while significantly lowering water usage.

The facility’s high-reflectance TPO (Thermoplastic Polyolefin) roofing and concrete hardscapes help limit heat absorption and reduce the urban heat island effect. At the same time, electric vehicle charging stations support both passenger cars and refrigerated transport trailers, allowing trucks to reduce diesel emissions during idle periods.

Energy efficiency extends throughout the interior as well. The building is illuminated entirely with LED lighting and paired with an enhanced thermal envelope and premium insulation systems, the warehouse achieves up to a 32% improvement in energy performance compared to conventional cold storage buildings.

The use of low-emission adhesives, sealants, and flooring materials also contributes to healthier indoor air quality and aligns with modern green building standards.

The building incorporates low-VOC materials, low-carbon footprint components, recycled content, and transparent product declarations, contributing significantly to its LEED Gold certification.

Taken together, these features make the Wilmington facility one of the most sustain able cold storage operations in the United States, setting a benchmark for environmentally responsible industrial design.

Engineering Challenges

A significant challenge arose when the project transitioned from speculative to build-to-suit after obtaining permitting.

“The tenant’s operational needs required major design revisions – ranging from advanced refrigeration systems to adding blast freezing capabilities with VNA racking – without derailing the timeline,” O’Connor says.

Evans managed more than 160 change orders, spanning scope modifications, manpower allocation, equipment procurement, and schedule adjustments. Thanks to rigorous design coordination meetings and an emphasis on open communication between the developer, tenant, and subcontractors, the team was able to adapt seamlessly, avoiding costly delays.

From a construction standpoint, the project pushed boundaries in both engineering and coordination. The VNA slabs, engineered and poured by Fricks, were installed atop 40 psi under-slab insulation in eight-foot-wide strips throughout the freezers and QFM room.

To keep the project on schedule, Evans coordinated daily slab pours, carefully managing curing times while simultaneously maintaining site access for other trades. This level of coordination was crucial in a project where nearly every sequence overlapped with critical-path activities.

Operational resilience was another core focus. The facility features backup power systems that can operate the refrigeration equipment at 75% capacity for up to 24 hours during an outage, ensuring product integrity is protected even in emergencies. Life safety systems are also fully backed by emergency generators, a necessity in a facility storing millions of pounds of perishable goods.

Key Features

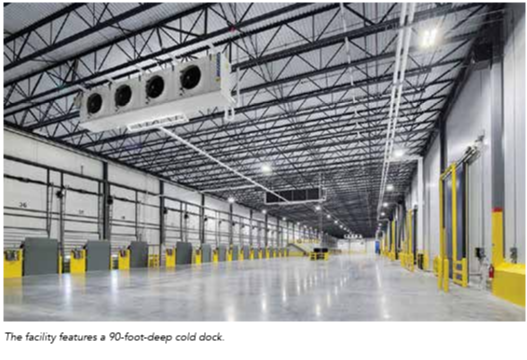

The facility features a 90-foot-deep cold dock, a blast freezer operating at -10°F with slating and de-slating areas and VNA racking, two -10°F storage freezers, a water storage tank and pump house, 10,000 square feet of office space integrated into the 277,300-square-foot warehouse, and advanced CO₂ refrigeration systems.

The facility incorporates a transcritical CO₂ refrigeration system designed by M&M Carnot, marking RL Cold’s most efficient cooling system yet.

A Collaborative Team

The project relied on an all-star roster of subcontractors, with 25% of all trades members of the Controlled Environment Building Association (CEBA). From design consultants and field crews to equipment suppliers, Evans tapped both local talent and national expertise, ensuring best-in-class execution at every stage.

“The success of the project was driven by the strength of collaboration,” O’Connor says. “Evans and RL Cold had a strong, trusted partnership, reinforced by seamless coordination with subcontractors and consultants. This high level of teamwork ensured that challenges were met head-on and that the project’s goals were achieved without compromising quality, budget, or schedule.”

A Model for the Future

Combining cutting-edge refrigeration technology, resilient backup systems, sustainability measures, and flexible design, this cold chain facility is both a logistical powerhouse and a model of modern industrial development.

With Evans delivering the project on time, on budget, and to an uncompromising level of quality, RL Cold’s Wilmington facility stands as a benchmark for future cold storage projects nationwide.

Media Contact

For media inquiries, please contact: Lindsay Shelton-Gross, Senior Vice President, Global Communications, Marketing and Strategic Initiatives, Global Cold Chain Alliance.